The automotive industry would not be what it is today without car manufacturing robots. They have certainly made manufacturing automobiles a lot easier. The manufacturing industry incorporates robots on the production floor for any number of reasons.

In the automotive industry, robotic manufacturing helps to boost a company’s competitive advantage. In addition, they give the company the following benefits:

- They bring down the costs of warranty

- Take over dangerous and dirty tasks from the human workforce

- Increase production speed, volume and quality

- Enhance safety in the workplace

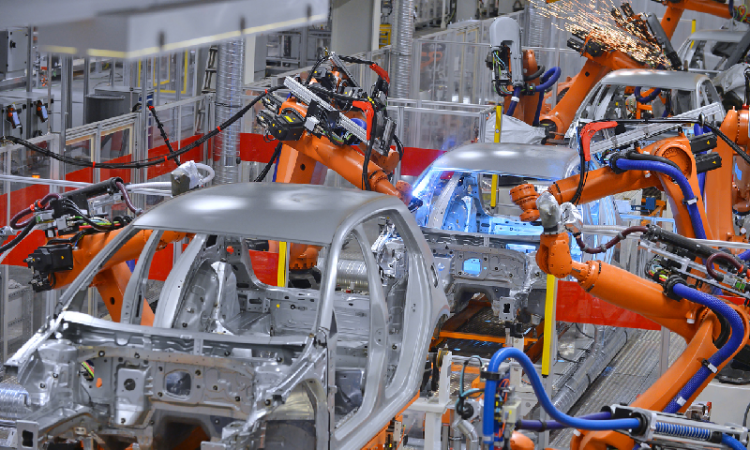

Automotive assembly plants utilize automotive robots for tasks such as spot welding and painting. However, they are also used for many other purposes on the assembly line. The automotive industry requires robots for the following main reasons:

- Volume in production

- Product quality

- Safety on the work floor

Volume in Production

A huge advantage robots have over humans is that they do not get fatigued. Their cycle times are consistent as long as they are operating. Automotive suppliers must always have some inventory in order to safeguard against delays in production.

Part manufacturers must endeavor to be consistent in time as well as process control in the production line. One tiny setback can bring an entire assembly line to a halt.

Robots help to guard against issues such as these as they can work nonstop. Hence, the rate of production does not slow down.

Product Quality

There is no comparison when it comes to repeatability in robots and humans. Humans are simply not built for doing the same thing over and over all day. Robots are programmed to perform repetitive tasks.

Unlike humans, they do not get bored, distracted or exhausted. They will not drop parts. The error margin with robots is almost nonexistent.

With their vision sensors, they can perceive variation in materials and adjust their programs to accommodate them. This results in consistently good quality products to the delight of the customers. In addition, warranty costs are reduced.

Safety on the Work Floor

Automotive manufacturing involves some of the most dangerous tasks in the manufacturing industry. There are exceeding heavy parts to be lifted and moved. Some of the tasks may involve climbing to dizzying heights to work on a part or handling molten metal.

Lifting heavy objects constantly could damage your musculoskeletal system. You could suffer from pulled muscles or simply throw your back and suffer agonizing pain. The chances of accidents due to human error are also very high.

Robots are machines and they cannot suffer any setbacks due to accidents. Simple repairs will be done and the machine is back in action. As has often been said, the human body has no spare parts. When robots take over hazardous tasks, they save humans from the risk of injury.

Applications for Automotive Robots

Motor vehicles are very intricate machines requiring lots of parts to put them together. This leads to an astonishing volume of manufacturing processes to get the parts fitted and working. Robotic automation makes it not only easier but also faster to build your favourite vehicles.

Some of the essential applications carried out by automotive robots include the following:

- Welding:Spot welding requires robots that have an adequate reach and high payload.

- Assembly: This includes windshield installation, wheel mounting and screw driving tasks performed by robotic arms.

- Machine Tending:Loading and unloading of parts onto the machines.

- Material Removal:Tasks such as cutting and light trimming.

- Part Transfer: For instance, getting a metal stamp from one press to the next one.

- Painting, Coating and Sealing: These tasks require precision to give a car a uniform look throughout its body.

Conclusion

Vehicle assembly plants could be said to be the largest customers of robot manufacturers. They rely on them for the most intrinsic as well as dangerous manufacturing tasks. Technological advancements have resulted in robots that are easier to program.

Automotive robots are designed and built to provide solutions that are unique to automotive manufacturing. Manufacturers should choose a knowledgeable automotive robotics provider to get the appropriate robots as well as installation.